The Future is Automated: How Battery Recycling Automation Systems Are Powering Green Tech in 2026

Estimated reading time: 12 minutes

Key Takeaways

- Battery recycling automation systems are the critical technological response to the impending tidal wave of end-of-life EV batteries, combining robotics, AI, and advanced chemical processes.

- These systems are a cornerstone of eco tech innovation, drastically improving recovery rates, enhancing worker safety, and reducing the environmental footprint of battery production.

- By enabling a circular economy for critical minerals, automation provides smart sustainability solutions that stabilize supply chains and reduce reliance on new mining.

- The battery recycling market is on a meteoric rise, projected to reach USD 24.36–32.28 billion by 2026, driven by policy and the global EV boom.

- While high capital costs and design standardization remain hurdles, government funding and industry alliances are rapidly scaling these essential green tech in 2026 solutions.

Table of contents

- The Future is Automated: How Battery Recycling Automation Systems Are Powering Green Tech in 2026

- Key Takeaways

- The Coming Tidal Wave: Why Automation is Now Imperative

- Defining the Revolution: What Are Battery Recycling Automation Systems?

- Eco-Tech Innovation in Action: Key Advancements

- Beyond Efficiency: Automation as a Smart Sustainability Solution

- The 2026 Horizon: Integrating Automation into the Green Tech Landscape

- Challenges and Considerations for the Path Forward

- Frequently Asked Questions

The electric revolution is accelerating at a breathtaking pace. Global electric vehicle (EV) sales surged to 17 million in 2024 and are projected to exceed 20 million in 2025, a powerful testament to our shift away from fossil fuels (source). But this remarkable progress comes with a looming shadow: an exponential growth in end-of-life battery waste. This isn’t just a future problem—it’s a present-day logistical and environmental challenge demanding an innovative response.

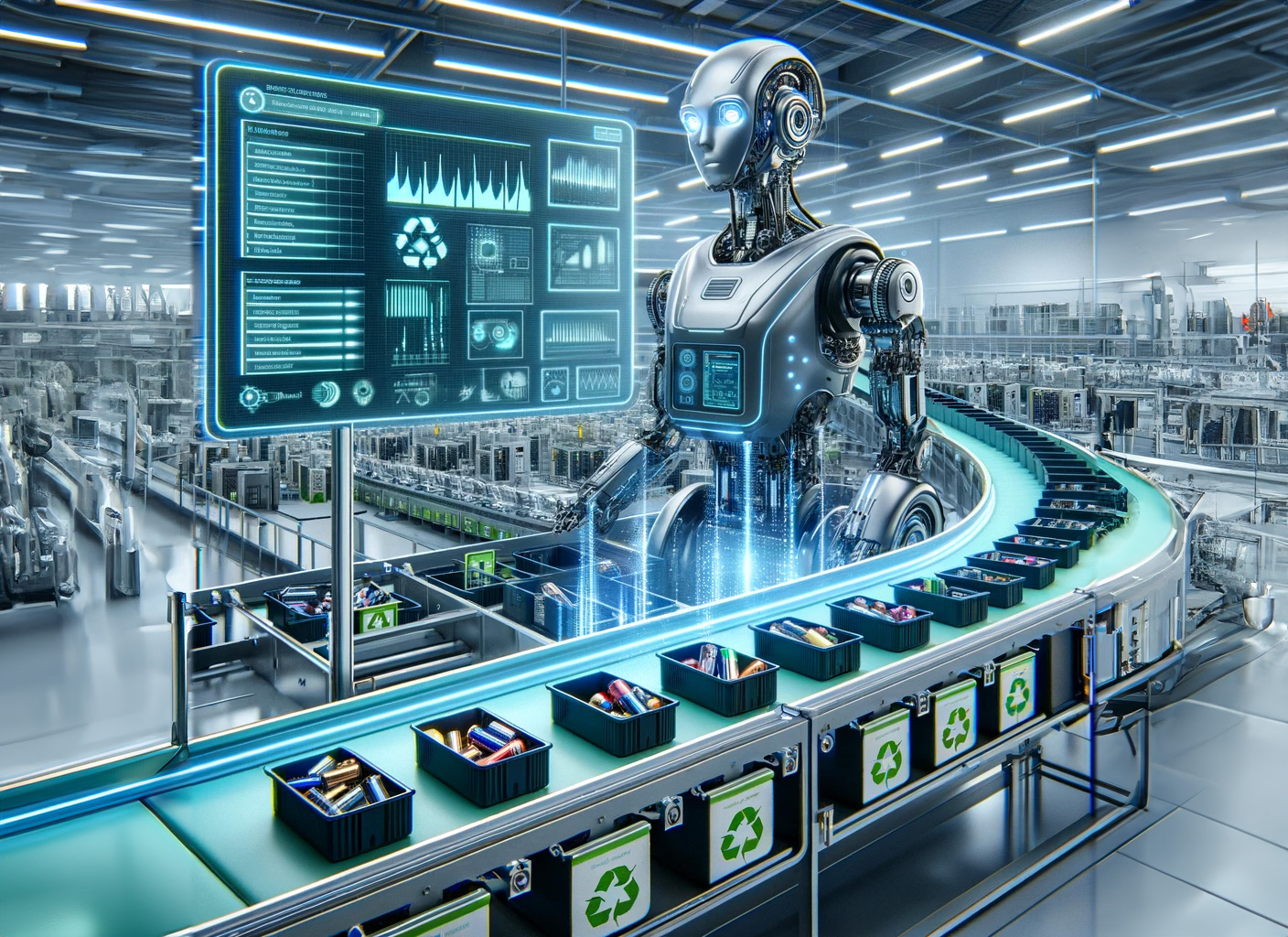

That response is battery recycling automation systems, the critical linchpin in the emerging circular economy for critical minerals. These sophisticated systems represent the forefront of eco tech innovation, efficiently recovering valuable materials like lithium, cobalt, and nickel to feed back into the supply chain (source). More than just machines, they embody a new paradigm in smart sustainability solutions, where waste is systematically transformed into resource. This represents a key frontier in how AI is transforming various industries, moving from theoretical potential to tangible, planet-saving application.

This exploration delves into how these automated systems are defining green tech in 2026, turning a critical waste stream into a strategic asset and powering a cleaner, more resource-secure future.

The Coming Tidal Wave: Why Automation is Now Imperative

The numbers don’t lie. The sheer volume of batteries approaching their end-of-life is creating an urgent economic and environmental imperative. Traditional, labor-intensive recycling methods are ill-suited for the scale, complexity, and potential hazards of modern lithium-ion batteries. Manual disassembly is slow, dangerous due to risk of short-circuit and fire, and inconsistent in material recovery.

Automation is no longer a luxury; it’s a necessity for scalability, safety, and profitability. It’s the only way to process millions of batteries with the precision required to meet the purity standards for new battery production. As we stand at the cusp of this waste wave, battery recycling automation systems are the engineered seawall—a fusion of mechanical prowess and digital intelligence built to manage the deluge.

Defining the Revolution: What Are Battery Recycling Automation Systems?

At its core, a battery recycling automation system is an integrated technological ecosystem designed to safely and efficiently process end-of-life batteries from receipt to purified raw material. It replaces human hands with a seamless, tech-driven workflow:

- Robotic Dismantling: Custom robotic arms, guided by advanced sensors, perform the precise and hazardous task of disassembling battery packs, removing modules, and separating cells without risk of thermal runaway.

- AI-Driven Sorting & Analysis: Using sophisticated computer vision and machine learning, these systems scan, identify, and categorize batteries by chemistry, size, and state of health in milliseconds, ensuring optimal routing for downstream processing (source).

- Advanced Chemical Processing: The heart of material recovery. Two primary methods are automated:

- Hydrometallurgy: The dominant process, holding a 49.17% market share in 2026. It involves shredding batteries into “black mass” and then using aqueous chemistry (acids and solvents) to selectively dissolve and precipitate out high-purity metals like lithium, cobalt, and nickel (source). It’s favored for its superior recovery rates, especially for lithium, lower energy consumption, and reduced emissions.

- Pyrometallurgy: A high-temperature smelting process that recovers a cobalt-nickel alloy but often loses lithium to slag. While older, it’s being refined and integrated into hybrid approaches.

The benefits of this automated approach are transformative:

- Sky-High Recovery Rates: Automated systems can achieve material recovery rates significantly higher than manual processes, often exceeding 95% for key metals, maximizing economic and resource yield.

- Unmatched Safety: By minimizing human exposure to toxic chemicals, high voltages, and fire risks, automation creates a fundamentally safer working environment.

- Massive Scalability: These systems are designed for high-throughput, 24/7 operation, making them the only viable solution to handle the projected millions of tons of battery waste efficiently (source).

Eco-Tech Innovation in Action: Key Advancements

The current wave of eco tech innovation in this field is nothing short of revolutionary. It’s not just about doing old things faster; it’s about doing entirely new things with intelligence and precision. These advancements are part of a broader wave of 10 cutting-edge AI technologies shaping the future.

- AI-Powered Vision Systems: Beyond simple sorting, next-gen AI can diagnose battery state-of-health, detect internal damage, and determine the most profitable recycling pathway—all in a non-invasive scan.

- Precision Robotic Disassembly: Robots equipped with force feedback and 3D vision can unscrew, cut, and separate components with sub-millimeter accuracy, preserving more material in a reusable state and preparing ideal feedstock for chemical recovery.

- Automated Black Mass Processing: The optimization of leaching, filtration, and electrochemical steps to extract individual metals from the shredded battery residue with minimal waste and energy input (source).

This innovation is already moving from pilot plants to global scale. Real-world examples showcase the ambition:

- Umicore is scaling towards a 150,000-tonne annual capacity plant by 2026, heavily reliant on AI vision and robotics (source).

- Redwood Materials, backed by a USD 3.5 billion investment, aims to supply 30% of the critical minerals for U.S. battery production through its highly automated processes (source).

- American Battery Technology Company (ABTC) received USD 150 million in DOE funding in 2024 specifically to scale its automated, integrated recycling system (source).

- Industry giants like CATL are investing billions (CNY 8 billion by 2028) into closed-loop, automated battery ecosystems (source).

Beyond Efficiency: Automation as a Smart Sustainability Solution

The impact of battery recycling automation systems extends far beyond factory efficiency. They are the engine of a smart sustainability solution that addresses multiple global challenges simultaneously. This push is a core component of next-level AI-powered sustainability efforts.

1. Enabling the Circular Economy: Automation makes it economically and technically feasible to close the loop on critical minerals. By reclaiming lithium, cobalt, and nickel from waste, we drastically reduce the environmental and social costs of new mining. In the U.S. alone, recycling capacity hit 35,500 tons in 2023, with a staggering 198,000 more tons of capacity in the immediate pipeline (source).

2. Securing Supply Chains & Stabilizing Costs: Geopolitical tensions and concentrated mining create volatile markets. Automated recycling creates a domestic, reliable source of materials, insulating EV manufacturers from price shocks and import dependencies. Recovered materials can be fed directly back into gigafactories, creating resilient regional supply loops.

3. Regulatory Compliance & Brand Value: With governments worldwide enacting stringent recycling mandates and Extended Producer Responsibility (EPR) laws, automation is the most effective way for companies to comply. It also fulfills the growing consumer and investor demand for verifiable, sustainable practices, turning a compliance cost into a brand and competitive advantage (source).

The 2026 Horizon: Integrating Automation into the Green Tech Landscape

By 2026, battery recycling automation systems will be deeply integrated into the fabric of green tech in 2026. The market itself is projected to reach a value between USD 24.36 billion and USD 32.28 billion, growing at a compound annual growth rate (CAGR) of 12.5% to 13.95% through 2030-2034 (source). This growth is fueled by an EV fleet projected to reach 240 million by 2030 and policies like the U.S. Inflation Reduction Act’s Section 45X tax credits, which incentivize domestic content (source).

Key trends defining this horizon include:

- Integration with Renewable Infrastructure: Future recycling plants will be powered by adjacent solar or wind farms, and their operation will be optimized using smart grid data, making the entire lifecycle of a battery increasingly carbon-neutral.

- The Rise of “Urban Mining”: Automated micro-factories located near urban centers will treat e-waste and end-of-life batteries as high-grade urban ore, minimizing transportation emissions and creating local jobs.

- Digital Product Passports & Blockchain: Coupled with AI, these digital ledgers will provide a cradle-to-grave history for every battery, containing precise data on chemistry and components. This allows automated systems to pre-plan the optimal recycling strategy before a battery even arrives at the facility, maximizing efficiency (source). This evolution mirrors the broader trajectory of technology from niche to mainstream, similar to the evolution of smart home technology.

Challenges and Considerations for the Path Forward

The path forward for this critical eco tech innovation is not without its obstacles. Acknowledging and addressing these challenges is key to successful scaling:

- High Capital Intensity: Building a fully automated, large-scale recycling facility requires massive upfront investment, as seen with Redwood Materials’ multi-billion-dollar campuses (source). This can be a barrier to entry and requires innovative financing models.

- Lack of Standardization: The myriad of battery sizes, formats, and chemistries (NMC, LFP, etc.) makes automated disassembly and sorting complex. Industry-wide design-for-recycling standards are urgently needed.

- Evolving Regulatory Frameworks: The regulatory landscape is still developing. Companies must navigate differing rules across regions regarding transportation, storage, and processing of spent batteries.

Yet, the momentum to overcome these hurdles is strong. Government support is materializing, such as the U.S. Department of Energy’s USD 44.8 million in funding for recycling R&D in 2024 (source). Furthermore, tech alliances between automakers, battery producers, and recycling startups are accelerating innovation and creating the integrated ecosystems necessary for success.

Frequently Asked Questions

What exactly is a battery recycling automation system?

A battery recycling automation system is an integrated suite of technologies—including robotics, artificial intelligence (AI), computer vision, and automated chemical processing—designed to safely, efficiently, and at scale dismantle end-of-life batteries and recover valuable constituent materials like lithium, cobalt, and nickel for reuse in new batteries.

Why is automation considered critical for battery recycling?

Automation is critical for three main reasons: Safety (minimizing human exposure to hazardous materials and high-voltage components), Scale (processing the millions of tons of batteries expected from the EV revolution), and Recovery Efficiency (achieving the high material purity and yield rates needed to make recycled content competitive with virgin mined materials).

How does AI contribute to these automated systems?

AI, particularly machine learning and computer vision, is used to rapidly identify and sort batteries by chemistry, model, and condition. It can also optimize the chemical recovery processes in real-time, predict maintenance needs for machinery, and manage the complex logistics of the entire recycling workflow, making the system smarter and more efficient over time.

What’s the difference between hydrometallurgy and pyrometallurgy in recycling?

Hydrometallurgy uses aqueous chemical solutions to dissolve and separate metals from shredded battery material (“black mass”). It is known for high recovery rates, especially for lithium, and lower energy use. Pyrometallurgy uses high-temperature smelting to recover metals as an alloy, but often loses lithium. Hydrometallurgy is becoming the dominant automated process due to its precision and environmental profile.

Are recycled materials from automated systems as good as new?

Yes, when processed through advanced automated hydrometallurgical systems, recovered lithium, cobalt, and nickel can be refined to a purity equal to or exceeding that of mined materials, making them fully suitable for manufacturing new, high-performance batteries. This “closed-loop” quality is essential for the technology’s success.

What is the biggest challenge facing the widespread adoption of this technology?

The single largest challenge is the high capital cost of establishing large-scale, automated facilities. While operating costs are lower and outputs valuable, the significant upfront investment requires strong partnerships, government support, and long-term offtake agreements with battery makers to de-risk the financing.