Robots on the Sidewalk: Jersey City’s Pilot and the Future of Food Delivery

Estimated reading time: 8 minutes

Key Takeaways

- The latest autonomous delivery robot news highlights a major city-backed pilot in Jersey City, deploying 20 AI-powered robots for restaurant deliveries.

- This urban logistics automation offers a zero-emissions solution to last-mile challenges, reducing traffic and costs in dense urban areas.

- Advanced ai navigation systems combining sensors, computer vision, and machine learning are the brains behind safe, reliable sidewalk navigation.

- Key delivery tech trends like Robots-as-a-Service (RaaS) and the rise of humanoid robots are converging to reshape the logistics landscape.

- While pilots show promise, scalability faces hurdles like public acceptance, regulatory frameworks, and technical challenges in adverse weather.

Table of contents

- Robots on the Sidewalk: Jersey City’s Pilot and the Future of Food Delivery

- Key Takeaways

- The Heights Pilot: Robots Hit the Sidewalks

- Urban Logistics Automation Takes Center Stage

- AI Navigation Systems: The Brains Behind the Brakes

- Delivery Tech Trends Shaping Tomorrow’s Logistics

- Navigating Hurdles: The Path to Scale

- Frequently Asked Questions

Imagine a quiet whirring sound on the sidewalk, a friendly-looking box on wheels politely waiting for a pedestrian to pass before continuing its journey. This isn’t science fiction; it’s lunchtime in Jersey City. In the latest autonomous delivery robot news, Coco Robotics has launched a landmark, city-backed pilot in The Heights neighborhood, deploying 20 AI-powered sidewalk robots to partner with local restaurants. This initiative marks a significant, high-impact expansion in the quest to solve urban last-mile logistics, bringing the future of contactless, efficient delivery directly to our curbs.

This technology presents a critical solution for modern cities: zero-emissions, efficient deliveries in dense areas. By taking to the sidewalks, these robots reduce traffic congestion, lower parking demands, and cut costs for both merchants and residents—all without adding a single new vehicle to the road. This pilot is a direct response to rising consumer demand for sustainable and contactless solutions, a key part of the broader delivery tech trends actively reshaping how our cities move goods. As these sleek machines navigate bustling neighborhoods, they represent more than just a novel way to get a pizza; they symbolize a transformative shift in urban logistics automation.

The Heights Pilot: Robots Hit the Sidewalks

Jersey City’s pilot program is a textbook example of pragmatic innovation. Before a single delivery was made, Coco’s robots meticulously mapped the sidewalks of The Heights, learning every curb cut, fire hydrant, and crosswalk to ensure safe navigation. This careful groundwork is now enabling partnerships with local eateries, a model proven in cities like Los Angeles, Chicago, and Miami. The goal is clear: integrate seamlessly into the urban fabric to support local businesses.

This is not an isolated experiment. It reflects a powerful trend towards unbeatable AI-powered transportation and aligns with global advances like the breakthrough UK autonomous vehicle innovations happening on roads. The momentum is building rapidly. Consider the expansion of Serve Robotics, which has doubled its Jersey City territory in the past year and now delivers for over 100 restaurants via apps like Uber Eats and Grubhub.

Beyond last-mile delivery, automation is entering new culinary frontiers. Donatos Pizza is pioneering this space, not only piloting autonomous delivery vehicles in partnership with The Ohio State University but also launching a fully robot-operated pizza restaurant at John Glenn Columbus International Airport, offering 24/7 service. These examples highlight the two primary models emerging:

- Sidewalk Robots: Operating on pedestrian paths, like Coco’s units in Jersey City, designed for hyper-local delivery in walkable, high-density neighborhoods.

- Road Robots: Larger vehicles that travel on streets, often handling longer distances or larger payloads, as seen in some grocery delivery trials.

Jersey City, with a density of over 19,000 people per square mile, is the perfect testbed. This pilot demonstrates how urban logistics automation can alleviate the strain on infrastructure by reducing reliance on human drivers and their vehicles, a crucial component in the development of game-changing 5G-powered smart cities.

Urban Logistics Automation Takes Center Stage

The rise of delivery robots signifies a fundamental rethinking of urban logistics. For decades, the “last mile”—the final leg of a product’s journey to the consumer—has been the most expensive, inefficient, and congested part of the supply chain. Urban logistics automation via sidewalk robots directly attacks this problem.

The value proposition is multifaceted:

- For Businesses: Reduced delivery costs, expanded reach without a larger fleet, and a cutting-edge brand image.

- For Cities: Lower traffic volume, reduced carbon emissions, and decreased wear-and-tear on roads.

- For Residents: Faster, often cheaper deliveries, and quieter, cleaner streets.

This isn’t a replacement for all delivery but an optimization for specific scenarios. Dense, mixed-use neighborhoods with a high concentration of restaurants and apartments are ideal. The robots act as mobile, automated couriers, bridging the short gap between a merchant and a customer’s doorstep without the overhead of a car. As these pilots collect data and refine their operations, they lay the groundwork for a more responsive and sustainable urban ecosystem, where goods move as efficiently as data.

AI Navigation Systems: The Brains Behind the Brakes

The magic that allows a robot to navigate a crowded sidewalk safely is found in its sophisticated ai navigation systems. These systems are a complex fusion of hardware and software, turning a wheeled container into a perceptive urban explorer.

At their core, these navigation systems rely on three key pillars:

- Sensors: The robot’s eyes and ears. This suite typically includes LiDAR (which uses laser pulses to measure distance), cameras for visual recognition, and ultrasonic sensors for close-range detection. These sensors create a real-time, 360-degree map of the immediate environment, detecting obstacles from a pedestrian’s legs to a stray trash can from 10-20 meters away.

- Computer Vision: The system’s ability to interpret what it sees. Advanced algorithms process camera feed at rates of 30 frames per second or higher to identify and classify objects: Is that a person, a pet, a bicycle, or a stationary planter? This allows the robot to predict paths and make decisions, like stopping for a crossing pedestrian or navigating around a delivery truck blocking part of the path.

- Machine Learning: The robot’s accumulated experience. By training on vast datasets of mapped urban environments—including the pre-mapped sidewalks of Jersey City—the system learns to handle dynamic variables. It gets better at anticipating the flow of foot traffic, recognizing temporary obstacles like construction zones, and choosing the safest, most efficient path.

The proof is in the pavement. Coco’s platform, powering these navigation systems, has already completed over 500,000 zero-emissions deliveries. City leaders have noted their reliability even in harsh weather, a testament to the robustness of their sensor fusion and real-time adaptation capabilities. This trend extends beyond delivery boxes; the same principles of sensor fusion and AI-driven autonomy are accelerating in other forms, as seen in the rapid deployment of humanoid robots for structured logistics tasks.

Delivery Tech Trends Shaping Tomorrow’s Logistics

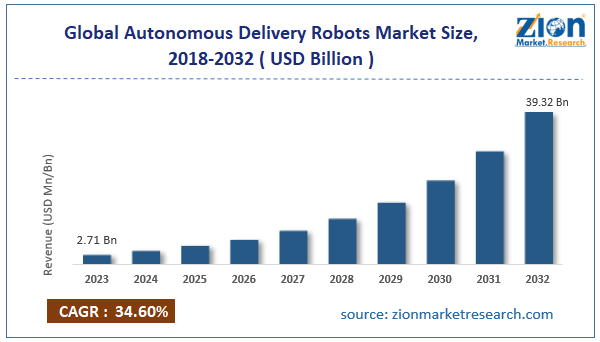

The sidewalk robots in Jersey City are just one piece of a larger, rapidly evolving puzzle. Several convergent delivery tech trends are setting the stage for a fully automated logistics future.

First is the shift to Robots-as-a-Service (RaaS) models. This allows restaurants and retailers to access automation without the massive upfront capital of purchasing robots. They pay a per-delivery or subscription fee, making robotic delivery scalable and accessible for small businesses—a model central to current pilots.

Second is the emphasis on sustainability. Electric-powered delivery robots produce zero direct emissions, addressing both environmental concerns and increasingly stringent urban emissions regulations. This aligns perfectly with post-pandemic consumer preference for contactless services.

Third, and perhaps most transformative, is the rise of humanoid robots in logistics. While still in earlier commercial stages, global installations reached 16,000 units in 2025, primarily in China for tasks like warehouse sorting and pallet moving. This signals a move towards more versatile automation. The competition is fierce: Tesla is accelerating its Optimus humanoid program for logistics applications, even as industry observers note China’s established dominance in manufacturing and deployment. This trend is part of the broader landscape of explosive AI drone technology and other automated systems.

Finally, the concept of micro-fulfillment is being revived. These small, automated warehouses located in urban centers allow for instant staging of e-grocery and retail orders, slashing last-mile delivery times from hours to minutes when paired with autonomous delivery systems.

Navigating Hurdles: The Path to Scale

Despite the exciting progress, the road to widespread urban logistics automation is not without speed bumps. Successfully scaling from focused pilots to city-wide integration requires overcoming significant technical, social, and economic hurdles.

Public Acceptance and Trust: A robot sharing space with children, pets, and the elderly requires immense trust. Pilots like Jersey City’s actively seek community feedback to build comfort and demonstrate safety. The unfamiliar can be unsettling, so transparency and proven reliability are key.

Regulatory and Infrastructure Frameworks: While city-backed programs show governmental support, clear, standardized regulations are still evolving. Cities need to establish rules for right-of-way, parking (or “standing”), speed limits, and operational zones. Furthermore, urban infrastructure itself may need subtle adaptations, much like it did for bicycles and scooters.

Technical and Environmental Limitations: Current ai navigation systems face challenges in extreme weather. Heavy rain can obscure cameras, and snow can cover crucial pavement markers. Sensors like LiDAR can see their accuracy reduced by more than 20% in thick fog. Many pilots, therefore, maintain hybrid human oversight ready to remotely assist robots in complex or degraded situations.

Economic Scalability: For humanoid robots specifically, high manufacturing costs and unproven return on investment (ROI) remain substantial barriers. Most commercial deployments are still in controlled environments like factories, with broader urban testing proceeding cautiously. The economic model for widespread adoption must be ironclad.

The trajectory, however, points upward. The industry is moving rapidly from pilot to expansion. Watch for new market entries, the growth of RaaS models, and significant production milestones—such as Chinese firms aiming for 100,000 cumulative humanoid units by 2027 and Tesla targeting mass production of its Optimus robot. This automated future is deeply interconnected, much like the rise of unstoppable AI-powered smart homes, creating a cohesive network of intelligent technology. The transformative potential of the latest autonomous delivery robot news is clear: paving the way for efficient, sustainable cities through advanced ai navigation systems and convergent delivery tech trends.

Will your city be next to welcome delivery robots on its sidewalks? Stay updated on the latest in automation and share your thoughts on the future of urban logistics in the comments below.

Frequently Asked Questions

How do delivery robots know where to go?

They use a combination of pre-mapped routes (like the detailed sidewalk maps created for Jersey City’s pilot) and real-time ai navigation systems. GPS provides a general location, while onboard sensors (LiDAR, cameras) allow them to precisely follow sidewalks, avoid obstacles, and locate the exact delivery address, often down to a specific door or building entrance.

Are delivery robots safe for pedestrians?

Safety is the paramount design focus. The robots are equipped with multiple sensor systems to detect people, pets, and objects from all directions. They operate at low walking speeds (typically 3-5 mph), are programmed to yield right-of-way, and come to a complete stop if their path is blocked. Most systems also have remote human monitors who can take control if a complex situation arises.

What happens if it rains or snows?

Adverse weather is a known challenge. While the robots are designed to handle light rain, performance can be limited in heavy precipitation, snow, or ice. Sensors can be obscured, and traction may be reduced. During such conditions, operations may be paused, or a greater level of remote human oversight may be utilized to ensure safety. This is an active area of technological development.

How do you get your food from the robot?

The process is designed for contactless pickup. When the robot arrives at your location, you receive a notification on your phone with a unique code or a link. You approach the robot, tap the screen or use your phone to authenticate, and a compartment securely unlocks, allowing you to retrieve your order. The entire interaction takes just seconds.

Will robot deliveries replace human delivery jobs?

In the near term, robots are more likely to augment than replace. They are ideal for short-range, high-density deliveries that are often unprofitable or stressful for human drivers using cars. This can allow human workers to focus on longer-distance deliveries, complex orders, or roles in logistics oversight, maintenance, and customer service. The technology may change the nature of some jobs while creating new ones in the process.